Livestock farming, and dairy farming in particular, produce large quantities of wastewater. This wastewater contains large amounts of organic matter, nitrogen, phosphorus and other pollutants that can cause significant environmental damage if not treated properly . A comprehensive and effective wastewater treatment plant for dairy farming ensures the proper disposal of this wastewater.

Why is wastewater treatment necessary for livestock?

Dairy wastewater has unique properties that distinguish it from typical municipal and industrial wastewater:

-

High organic load : The presence of animal waste leads to a significantly increased need for biochemicals and chemicals .

-

High nitrogen and phosphorus content – caused by urea and other compounds in animal waste.

-

High suspended solids : This includes food debris, waste, and other particles.

-

Unpleasant odours : are caused by the decomposition of organic matter under anaerobic conditions.

Improper wastewater treatment can lead to contamination of surface and groundwater, unpleasant odors, and health problems.

Types of wastewater on dairy farms

Wastewater from animal husbandry comes mainly from the following sources:

-

Washing of stables

-

Cleaning of milking machines

-

Wastewater from dairy farms

-

Polluted surface waters

Main Components of Livestock Farm Wastewater Treatment Complex

Main Components of Livestock Farm Wastewater Treatment Complex

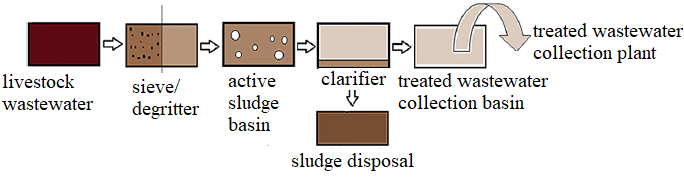

A wastewater treatment system for livestock typically involves the following steps:

1. Pre-treatment

-

Garbage disposal unit : Separates coarse materials such as feed and solid waste.

-

Primary clarifier : Separation of heavy particles

-

Grease trap : for separating floating grease

2. Primary cleaning

-

Coagulation and agglomeration : the use of chemicals to accelerate the sedimentation process.

-

Secondary sedimentation : separation of the clots formed

3. Secondary (biological) treatment

-

Aerobic : Use of aerobic reactors such as MBBR, SBR or activated sludge.

-

Anaerobic : In cases where the organic load is very high, UASB systems or septic tanks are used.

4. Endreinigung

-

Filtering : Use sand filters or fine filters.

-

Disinfection : Use of chlorine, ozone or ultraviolet light to disinfect wastewater.

5. Sludge management

-

Sludge thickening

-

Sludge digestion

-

Sludge drying

Benefits of Using a Livestock Wastewater Treatment System

-

Environmental protection: prevention of water and soil pollution

-

Water reuse : the possibility of using purified water for irrigation or washing.

-

Odour reduction : Improving hygiene on the dairy farm

-

Environmental Compliance : How to Avoid Fines

-

Reducing water consumption : water recovery and reuse

Factors Influencing the Design of a Livestock Wastewater Treatment Plant

-

Volume of waste water : depending on the number of animals and the work carried out.

-

Wastewater quality : BOD, COD, suspended solids, nitrogen and phosphorus values

-

Available space : determines the type of filtration system.

-

Investment and operating budget

-

Local Laws : Wastewater Discharge Regulations

Common technologies for the treatment of livestock wastewater

1. Pneumatic Systems

-

Activated sludge : suitable for medium and large dairy farms.

-

MBBR (Moving Bed Biofilm Reactor) : High efficiency in a small space

-

SBR (Sequencing Batch Reactor) : High operational flexibility

2. Anaerobic Systems

-

UASB (Upwelling Anaerobic Sewage Batch) : Suitable for wastewater with high organic load

-

Anaerobic biofilters : easy to use

3. Hybrid systems

Combination of aerobic and anaerobic methods for maximum efficiency.

Problems and solutions in the field of wastewater treatment in animal husbandry

1. Changes in wastewater quality and quantity

Solution : Design a flexible capacity system and use storage tanks.

2. High organic load

Solution : Use anaerobic pretreatment before aerobic plants.

3. Problems with the smell

Solution : Cover process units and use odor control systems.

4. Excessive sludge formation

Solution : Improve cleaning processes and use sludge thickening and water drying systems.

Maintenance and operation of a wastewater treatment plant for animal husbandry complexes

To achieve optimal system performance, please note the following:

-

Regular monitoring of quality standards

-

Preventive maintenance of equipment

-

Proper treatment of the resulting sludge

-

operative Schulung des Personals

-

Periodic calibration of measuring instruments

Cost of wastewater treatment for livestock

The cost of treatment depends on several factors:

-

Initial investment costs : Purchase and installation of the system

-

Operating costs : Energy, chemicals and labour costs

-

Maintenance costs : repair and replacement of parts

In the long run, however, these costs are economically justified because water consumption is reduced, environmental penalties are avoided and water can be reused.

Standards for the discharge of treated wastewater

Wastewater from a wastewater treatment plant must meet Environmental Protection Agency (EPA) standards. Key standards include:

-

BOD5 : maximum 30 mg/l

-

COD : maximum 60 mg/l

-

TSS : max. 30 mg/l

-

Total nitrogen : max. 10 mg/l

-

Total phosphorus : max. 2 mg/l

Reuse of treated wastewater

Clean water can be used in the following cases:

-

Irrigation of green areas and agricultural land

-

Washing of stables

-

Cooling

-

Groundwater recharge

Graduation

A wastewater treatment plant for livestock farms is not only ecologically necessary, but also a sensible investment. By choosing the right system and keeping it running properly, you protect the environment while reaping the economic benefits of water reuse. Thanks to advanced treatment technology, there are now compact and efficient systems that treat livestock wastewater in a space-saving and cost-optimized manner according to the required standards.

The final choice of a cleaning system should be based on a comprehensive assessment of the conditions of each dairy farm, taking into account technical, economic and environmental factors . Consultations with specialists in the field will help determine the best option and develop the ideal system.